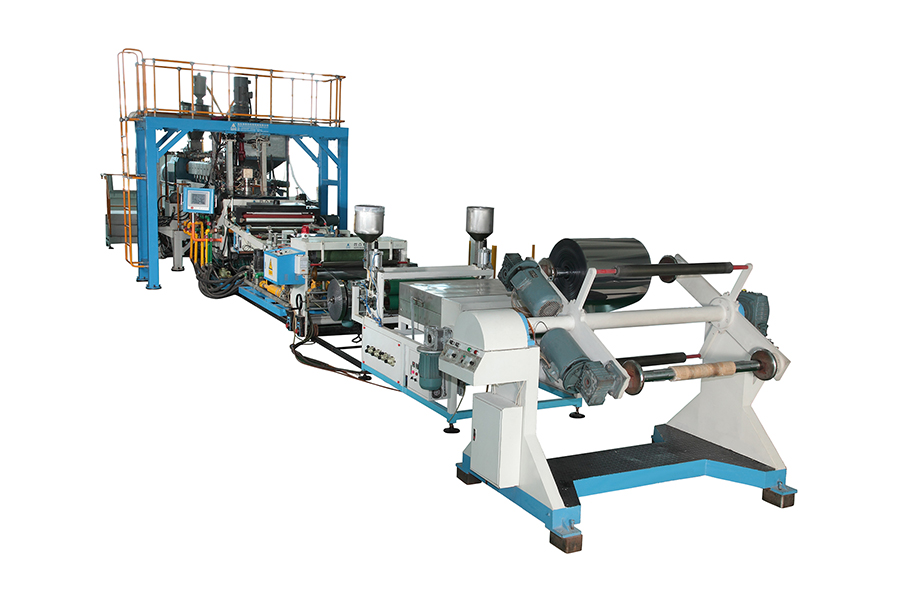

I-Twin Screw Plastic Extruder (PET Sheet Extrusion)

Ipharamitha Yezobuchwepheshe

I-WJP(PET)75B-1000 Twin Screw Plastic Extruder (PET Sheet Extrusion)

| Izinto ezisetshenziswayo | Ukucaciswa kwesikulufa | Ukujiya kweshidi | Ububanzi beshidi | Umthamo wokukhipha | Umthamo ofakiwe |

| mm | mm | mm | kg/h | kW | |

| APET, PLA | Φ75 | 0.18-1.5 | ≤850 | 300-400 | 280 |

Izici

1.Isici sesikulufa samukela isikulufu sentambo ephindwe kabili yohlobo lwe-conjugate enomklamo wokuthuthukisa ikhompuyutha kanye nomshini wokunemba. Ngaphandle kwalokho, isikulufu sakhelwe ngenhlanganisela ye-multivariate yokwakhiwa kwe-modular, enokuzihlanza okuphezulu nokushintshashintsha.

2. Ngokusekelwe eminyakeni yokuhlangenwe nakho komklamo wokucushwa kwesikulufa, i-AUTO ingakwazi ukwenza ukulungiselelwa okuphelele kwenhlanganisela yezinto zesikulufu ngosizo lobuchwepheshe besofthiwe. Ngakho-ke, ingakwazi ukubona ukudluliswa kwezinto ze-plasticizing, ukucwenga okuxubile, ukugunda nokuhlakazwa, i-homogenization, i-volatilization kanye ne-devolatilization, igcine ingcindezi kanye ne-extrusion kanye neminye imisebenzi ngokuya ngezinto zekhasimende kanye nokucubungula ubuchwepheshe.

3. Umphongolo womshini uklanywe ngezixhumi ezimbili ezikhipha amandla evacuum eziqinisekisa ukukhipha ngokugcwele umhwamuko wamanzi namanye amagesi aguquguqukayo.

4. I-twin screw plastic extruder idizayinelwe ngepompo yedosi encibilikayo eqinisekisa ukuphuma komthamo ngengcindezi eqinile, engasiza futhi ekutholeni ukulawulwa okuzenzakalelayo kweluphu evaliwe yokucindezela nesivinini.

5. Umshini ophelele wamukela uhlelo lokulawula lwe-PLC, olungakwazi ukubona ukulawula okuzenzakalelayo kokumiswa kwepharamitha, ukusebenza kwedethi, impendulo, ukwethusa neminye imisebenzi.

Inzuzo

Okunye okugqamile okuyinhloko kwama-twin screw plastic extruder yizikulufu zazo. Kuthathwe ukunakekela okukhulu ukuze kuqinisekiswe ukusebenza kahle okuphezulu nokuqina ngokusebenzisa isikulufu esihlanganisiwe sendiza ekabili. Lo mklamo oyingqayizivele uhlanganiswe nobuchwepheshe bokwenza kahle ikhompuyutha kanye nomshini wokunemba, okuholela ekusebenzeni okuphakeme. Ama-elementi esikulufu aphinde afake ukwakhiwa kwe-modular yokuzihlanza okuphakeme nokushintshana. Lokhu kuqinisekisa inqubo yokukhiqiza eshelelayo nengaphazamiseki, ukunciphisa isikhathi sokuphumula nokukhulisa umkhiqizo.

Iminyaka yolwazi edizayini yokumisa isikulufu isivumela ukuthi sithuthukise ukusebenza kwe-extruder. Ngosizo lobuchwepheshe besofthiwe esezingeni eliphezulu, singakwazi ukumisa kahle izinhlanganisela zezinto zesikulufu. Lokhu kusho ukuthi ama-extruder ethu angadlulisela kahle futhi enze ipulasitiki izinto ezibonakalayo, okuqinisekisa ukukhishwa okungaguquki kwekhwalithi ephezulu. Ubuchwepheshe bethu be-software budlala indima ebalulekile ekuzuzeni izimo zokusebenza ezifanele, ukuqinisekisa ukuthi amakhasimende ethu ayakwazi ukukhiqiza izinga eliphakeme kakhulu leshidi le-PET.

Enye inzuzo ebalulekile yama-twin screw plastic extruder ukuguquguquka kwawo. Noma ngabe ukhiqiza ishidi le-PET lokupakishwa, i-thermoforming noma olunye uhlelo lokusebenza, ama-extruder ethu angahlangabezana nezidingo zakho ezihlukile. Iyakwazi ukucubungula inhlobonhlobo yezinto, inikeze ukuguquguquka okukhulu enqubweni yakho yokukhiqiza. Ukwengeza, ama-extruder ethu enzelwe ukulungiswa okulula nokusheshayo, okukuvumela ukuthi ushintshe kalula phakathi kwamafomethi omkhiqizo ahlukene. Lokhu kuguquguquka konga isikhathi nemali, okwenza ama-extruder ethu abe yisixazululo esingabizi kakhulu sezidingo zakho ze-PET sheet extrusion.